Medical Device Prototyping: A Sunrise Labs Case Study

Explore how Sunrise Labs uses ProtoPie to create high-fidelity medical device prototypes.

.jpg)

The stakes in medical device design couldn't be higher. Safety is paramount, as even the smallest hiccup in the design can harm the health or well-being of the end users. This is Sunrise Labs' primary challenge.

So, what's the secret to navigating this high-pressure terrain? The answer lies in high-fidelity prototyping with ProtoPie, a tool that allows companies like Sunrise Labs to identify potential issues early and make multiple design iterations before moving into the development phase.

During our live stream, “Innovating for Health: Exploring Medical Device Prototyping,” Alex Therrien, who was the Director of User-Centered Design at Sunrise Labs at the time, explained how they utilize medical device prototyping to establish trust with their clients and stakeholders. Keep reading for his valuable tips on using ProtoPie for medical device prototyping, or watch the recording below.

Overview

- Introducing Sunrise Labs

- Why medical innovation is different

- How rapid prototyping supports innovation in medical device design

- How Sunrise Labs uses ProtoPie for medical device development

- Case study: developing a concept GUI for robotic surgery using ProtoPie

- Tips for using ProtoPie in medical device design

Introducing Sunrise Labs

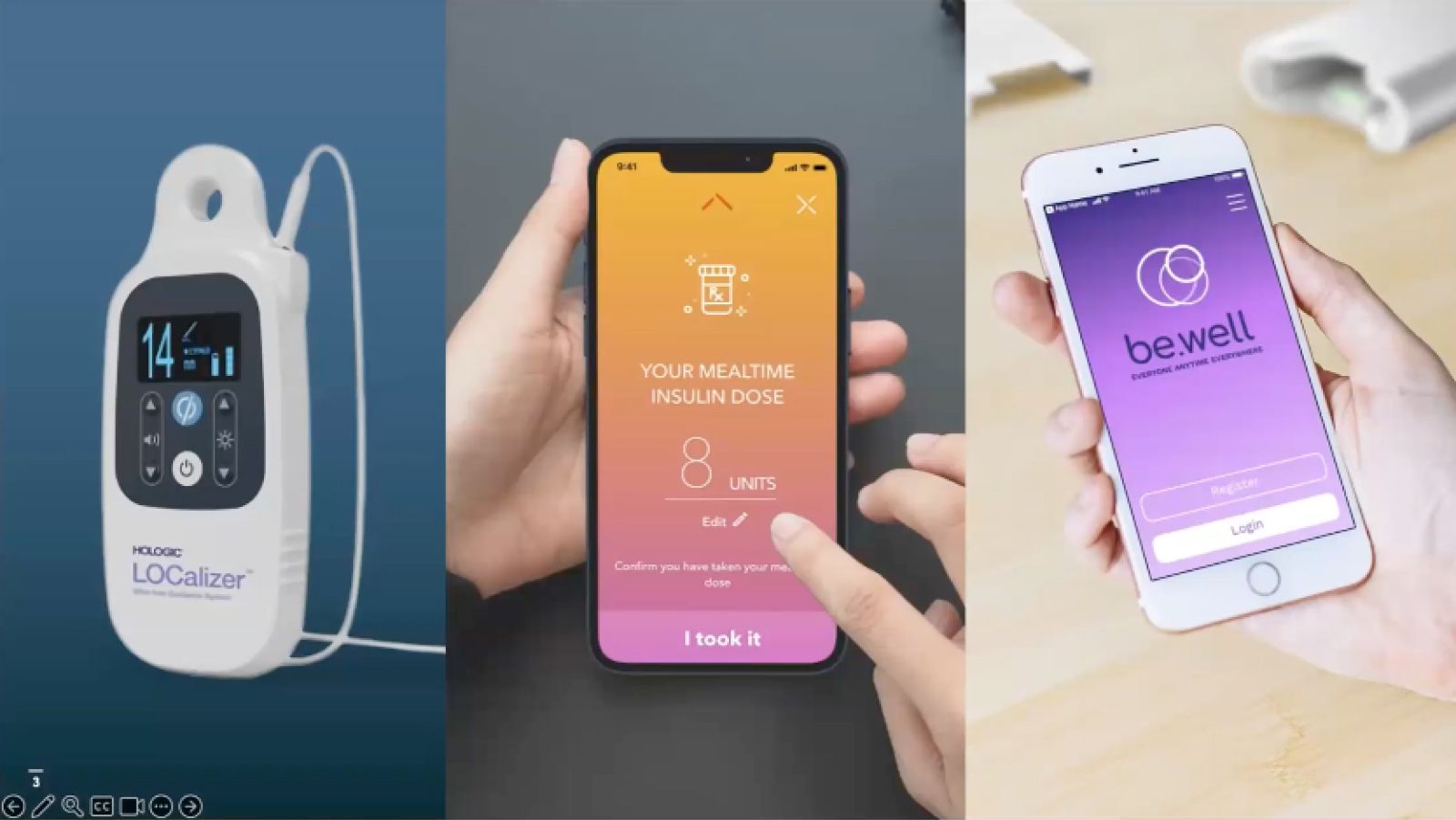

Sunrise Labs is a privately owned medical device consultancy in New Hampshire. Specializing in software-powered electro-mechanical devices, they work with a wide range of clients, from Fortune 500 companies to startups about to launch their first products.

While they don't limit themselves to specific sectors, Sunrise Labs have strong success in several areas, such as surgical devices, robotic surgery platforms, drug delivery infusion imaging, and diagnostics.

When Sunrise Labs develops a new medical device for a client, using high-fidelity prototyping to support innovation in medical devices is an important part of the process. The medical devices they create and the software that drives them are complex, often requiring multiple user interfaces to accommodate clinicians, patients, and caregivers. Each type of user will use the medical device in a different way and, therefore, should have a different, intuitive interface.

“Innovation is disruptive, by definition," says Alex. It can open markets, and ideally, it adds value to people’s lives. But in medical devices, there is a danger because we’re dealing with people’s health and well-being.”

Why medical innovation is different

Innovation can fail in medical device design in many ways, but the two major ones are product-market fit and a failure to reduce or remove harm to patients and users.

Sunrise Labs and their clients' collective goal is to ensure that innovation provides life-changing outcomes for the clients they serve.

However, delivering disruptive product-market fit safely is a huge task that encompasses multiple variables.

How rapid prototyping supports innovation in medical device design

In order to not “boil an ocean,” as Alex puts it, Sunrise Labs conducts frequent evaluations to test the user and stakeholder response to the many variables. High-fidelity prototyping in ProtoPie allows Sunrise Labs to unlock useful feedback in each of those evaluations.

Medical prototypes allow them to identify when there is a danger of poor product-market fit or a risk of harm to patients and users by providing reliable data in 3 key areas:

- barriers to adoption;

- the patient’s life;

- the role in the clinician's workflow.

1. Usability testing helps to identify barriers to adoption

By giving usability testers medical prototypes to use in their natural environment, Sunrise Labs can identify any areas of frustration or barriers to adoption that may be present.

For example, medical device designers can see if there are environmental or equipment limitations that may impact the effectiveness of the device or the likelihood of it being used. They can see if there are unforeseen usability issues that may risk harm to a patient or a user.

2. Medical prototyping helps integrate devices seamlessly into patient lives

The goal of innovation in medical device product design is to provide patients with medical solutions that enhance their quality of life. It is important to Sunrise Labs that the devices don’t turn the end user’s home into a hospital room or force them to lug around yet another cumbersome device.

Medical prototyping allows Sunrise Labs to see first-hand how the device will fit into the patient’s life and interact with the other aids and devices they use. The medical design team can identify possible points of friction and opportunities to streamline the patient’s routine.

3. Medical prototypes help assess how devices fit into clinician workflows

The clinicians' and doctors’ ability to use the device is another major concern of Sunrise Labs. Particularly whether the medical device is suitable for the environment in which it is used. Medical devices intended for use in operating theatres have different environmental requirements compared to medical devices being used in clinics.

“Our users aren’t always in charge of what they are allowed to do in the spaces that they work,” Alex explains.

Sunrise Labs needs to consider the data access clinicians have and whether the skill level or experience of the user may limit adoption. Medical device prototyping permits them to see if de-skilling their device and opening it up to more users can improve its benefits without creating unseen usability issues that could harm patients.

How Sunrise Labs uses ProtoPie for medical device development

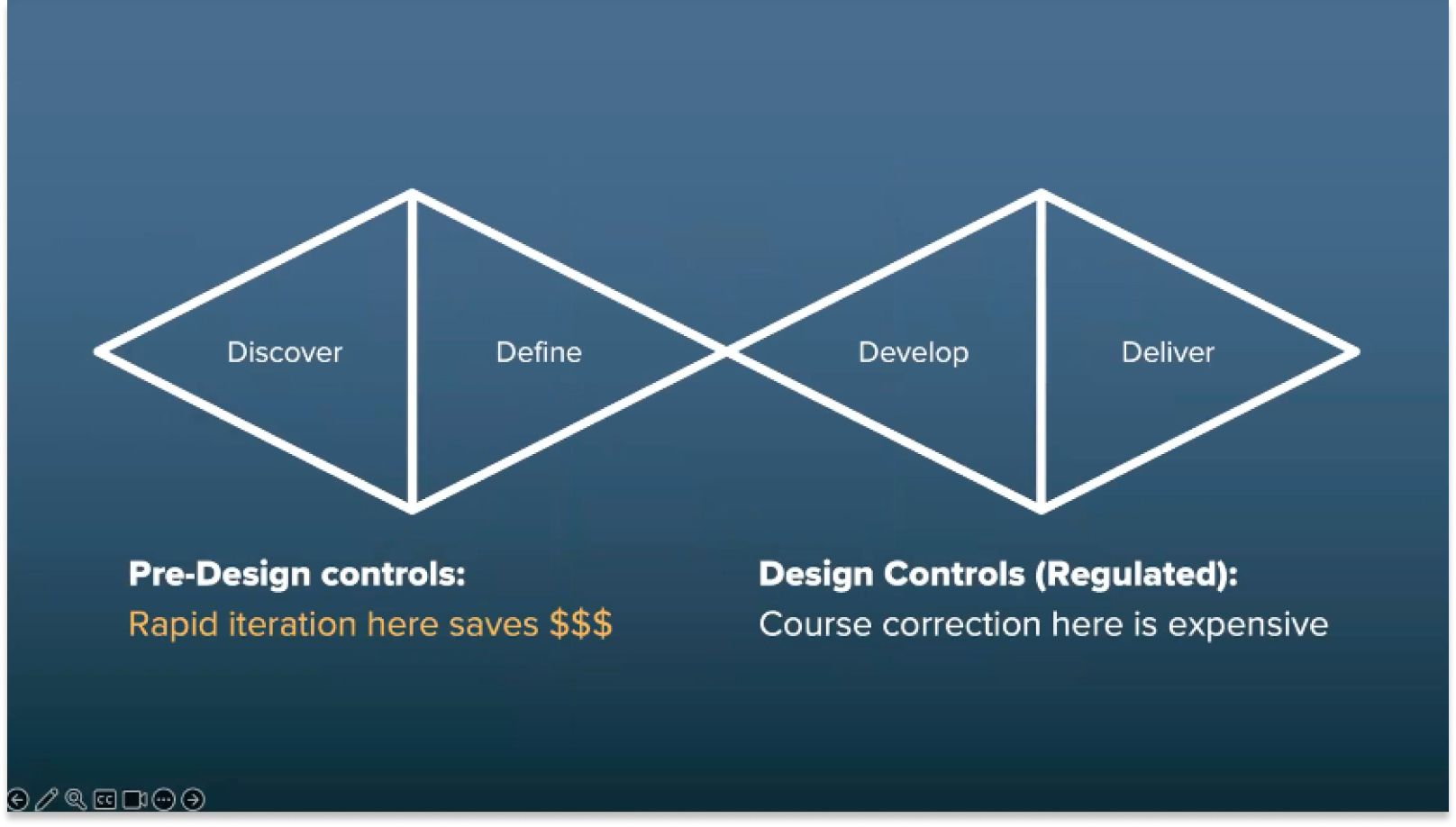

In medical device design, time is money, and rapid prototyping and constant iteration in the pre-development phase save a lot of it.

“Sunrise needs to move effectively and fail fast to be competitive in our space,” Alex says. Equally important is accuracy. The research data that Sunrise develops must build confidence and trust with their clients.

High-fidelity prototyping allows Sunrise to balance these priorities in the four following ways:

1. ProtoPie streamlines the design process for medical devices

Medical device prototyping in ProtoPie enables Sunrise Labs to test the product as much as possible and make agile changes to address issues. In this way, they can burn down most risks to product-market fit and usability before the project enters the less flexibly regulated development process.

Having ProtoPie in the middle allows Sunrise Labs to balance the complexity they need to achieve accuracy while still being able to evolve and change the design quickly, limiting perfectionism.

2. High-fidelity prototypes help establish trust with clients

ProtoPie’s features, like native keyboard inputs, allow demonstrations to be more immersive for clients. They can interact with the prototype as they would with the system, keeping clients and usability testers immersed in the experience.

“It’s surprising how clean that is for us to be able to exhibit what the intention of the system is," Alex says.

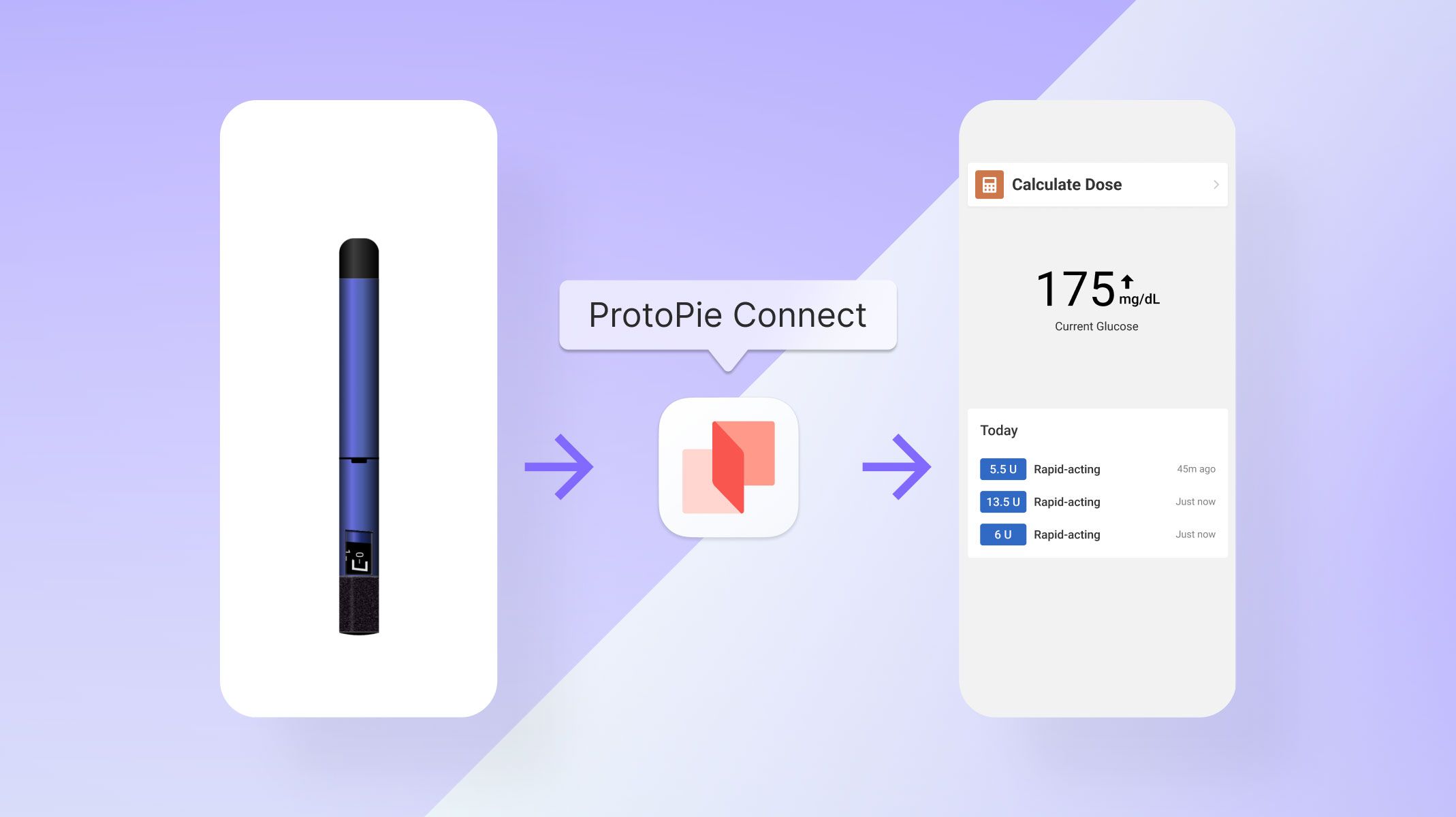

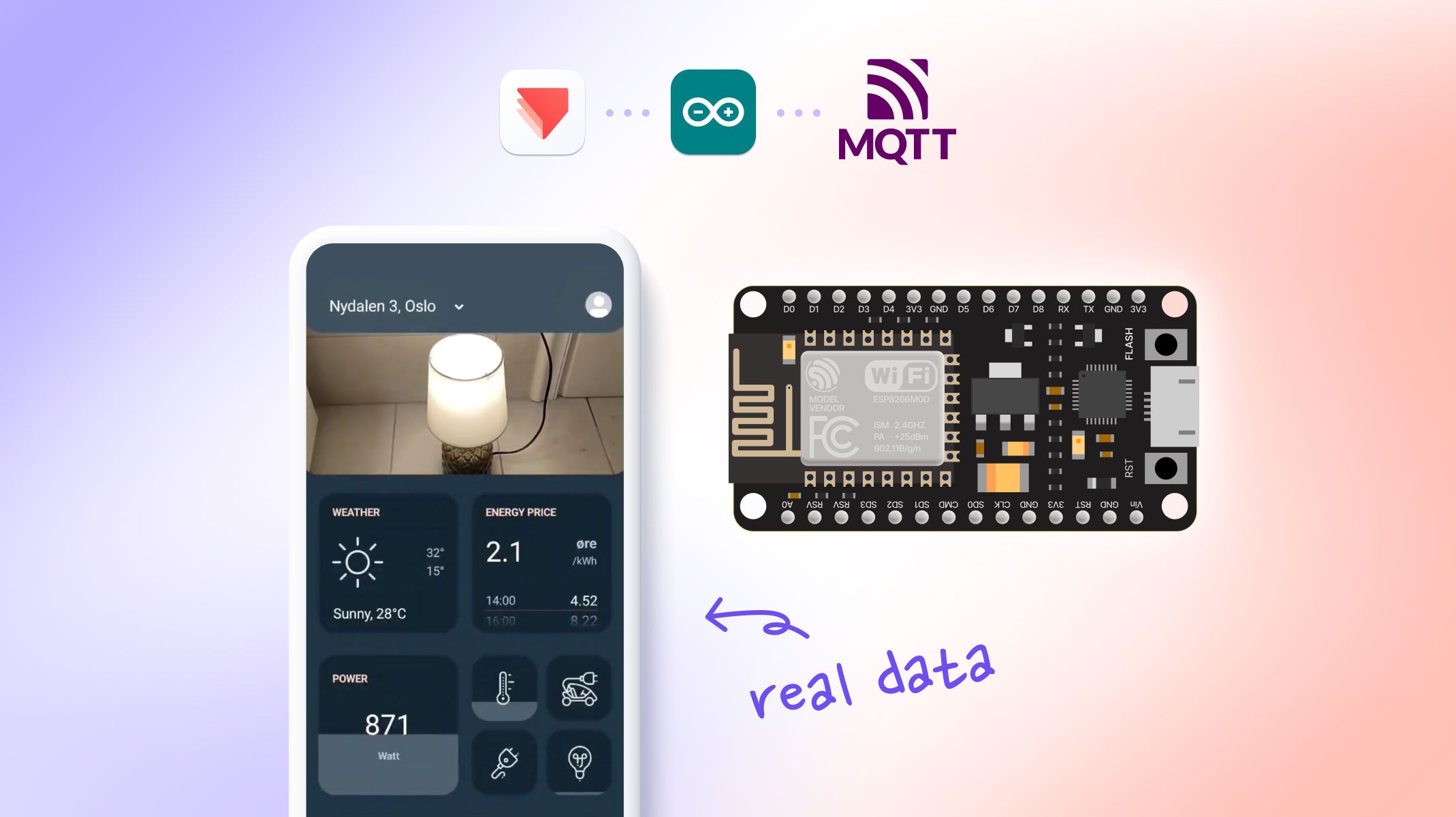

Sunrise Labs uses ProtoPie Connect and blokdots to model the whole user experience to their clients. This means they can see the whole medical device design, including:

- Hardware and software interactions;

- Buttons;

- LED indicators;

- Other physical interactions.

With a better understanding of the entire user experience, they can get the clients excited about the medical device. This also gives them something to show investors to demonstrate the market potential.

3. ProtoPie supports secure and efficient usability testing

Medical prototyping makes it easier for researchers at Sunrise Labs to see how usability testers interact with the medical device.

Researchers aren’t inadvertently leading the usability testers by telling them what would happen or what a user would do—the users are experiencing and reacting to it.

4. ProtoPie enables efficient team collaboration

The early stages of the medical device design at Sunrise Labs require multi-disciplinary teams to collaborate in the sprint process. High-fidelity prototyping has made collaboration, and especially communication, more effective in these stages. The outcomes are better because each team member can see what the others mean because they can demonstrate using the prototype.

As Alex puts it, “The less handwaving you have, the more effective hand-off is.”

Case study: developing a concept GUI for robotic surgery using ProtoPie

Prototyping is not exactly brain surgery—but Sunrise Labs did use ProtoPie to demo a concept GUI for a robotic surgery platform startup. Their client’s focus was the hardware, but they needed a concept GUI to allow investors to see the credibility of their product and how it fits into the clinical workflow.

Sunrise Labs would usually have a 12-week timeline for such a project, but the client’s demo was in 8 weeks. Although they were not using ProtoPie in their medical device prototyping process at this point, they had been considering it for some time. Based on what they knew about ProtoPie, they believed that ProtoPie could maximize the deliverables in such a limited timeframe.

“The learning curve of ProtoPie was surprisingly small for the power that it delivers. Our team was able to onboard themselves and start building low-fidelity during week one and start showing the promise,” Alex explains. “In the eight-week window, the MRI image navigation was able to be done.”

The startup CEO jumped into the MRI to provide the images that investors were navigating in the client’s demo.

Medical prototyping allowed the startup to respond quickly to any concerns that the investors or stakeholders had. For example, when the startup asked Sunrise Labs if the capacitive touchscreen display would present issues in the surgical environment—due to gloves, screen covers, and medical goo— Sunrise Labs was able to use their prototype to test and give them a response within an hour.

The process went as follows:

- They would create a full prototype and send it to the client.

- The client would get feedback from key opinion leaders, often well-known surgeons, and come back to Sunrise Labs with critical questions.

- Sunrise Labs was able to answer those questions and promptly modify or create a new prototype.

In the end, the startup's key opinion leaders were highly satisfied with the interface, which met all criteria for adoption and usability. The device is currently undergoing FDA approval for market release.

“Every client that we’ve delivered for with ProtoPie has gone out and bought it for themselves either to make edits or do other evolutions that don’t make sense to send out of the house,” Alex adds.

Tips for using ProtoPie in medical device design

- Name everything. Naming your layers, interactions, and triggers saves time during mid-build debugging. You can use the search function to find the layers you want to modify, speeding up the midway process.

- Prioritize based on criticality and difficulty. In order to maximize the results, Sunrise Labs prioritizes its medical prototyping process based on the features that are critical to the investor demonstration or user experience testing.

- Engage in tech de-risking iterations. Sunrise Labs advocates for a rapid 1-2 day iterative process that focuses purely on functionality. This allows for more efficient collaboration as the design team can layer visual elements over a functional core, enhancing both reliability and user experience.

- Start small and build up. It is easier to get excited by the big picture, but starting small with a single interaction and building up allows you to create a proven method. You can identify where the bugs occur and troubleshoot before adding complexity.

.png)

Streamline medical design prototyping with ProtoPie

Sunrise Labs and thousands of other companies are using ProtoPie’s high-fidelity prototyping to streamline their development process by identifying barriers to adoption before development begins. Join them today by trying ProtoPie for free!

.jpg)